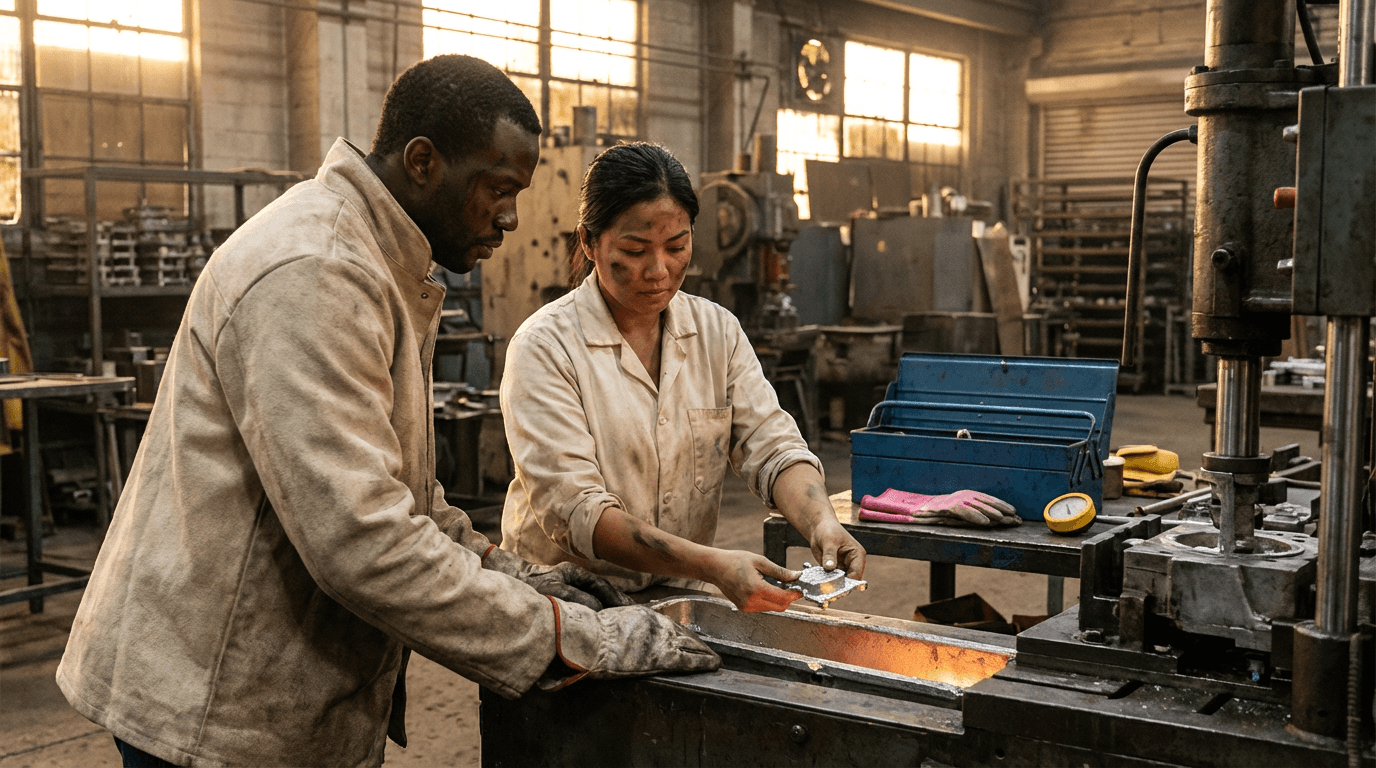

Die casting training

Gain mastery in aluminium die casting through practical metallurgy, process parameters, defect analysis, and troubleshooting. Learn to minimise porosity, cold shuts, and flash while enhancing quality, tool life, and cycle time on cold-chamber die casting lines.

flexible workload of 4 to 360h

valid certificate in your country

What will I learn?

Die Casting Training equips you with hands-on shop-floor skills to manage aluminium cold-chamber processes, adjust injection profiles, and configure melt, die, and intensification parameters for reliable quality. Master identifying and preventing defects such as porosity, cold shuts, and flash, implement SPC and real-time monitoring, adhere to stringent safety protocols, and employ systematic troubleshooting to lower scrap rates, minimise downtime, and boost casting efficiency.

Elevify advantages

Develop skills

- Optimise die casting parameters to quickly reduce porosity using proven Al-Si settings.

- Diagnose casting defects like porosity, cold shuts, and flash within hours.

- Control machines using data with SPC, shot profiles, and real-time alarms.

- Operate safe and efficient cold-chamber cells covering aluminium handling, PPE, and lockout procedures.

- Lead shop-floor trials by designing quick DOEs, documenting changes, and proving results.

Suggested summary

Before starting, you can change the chapters and the workload. Choose which chapter to start with. Add or remove chapters. Increase or decrease the course workload.What our students say

FAQs

Who is Elevify? How does it work?

Do the courses have certificates?

Are the courses free?

What is the course workload?

What are the courses like?

How do the courses work?

What is the duration of the courses?

What is the cost or price of the courses?

What is an EAD or online course and how does it work?

PDF Course