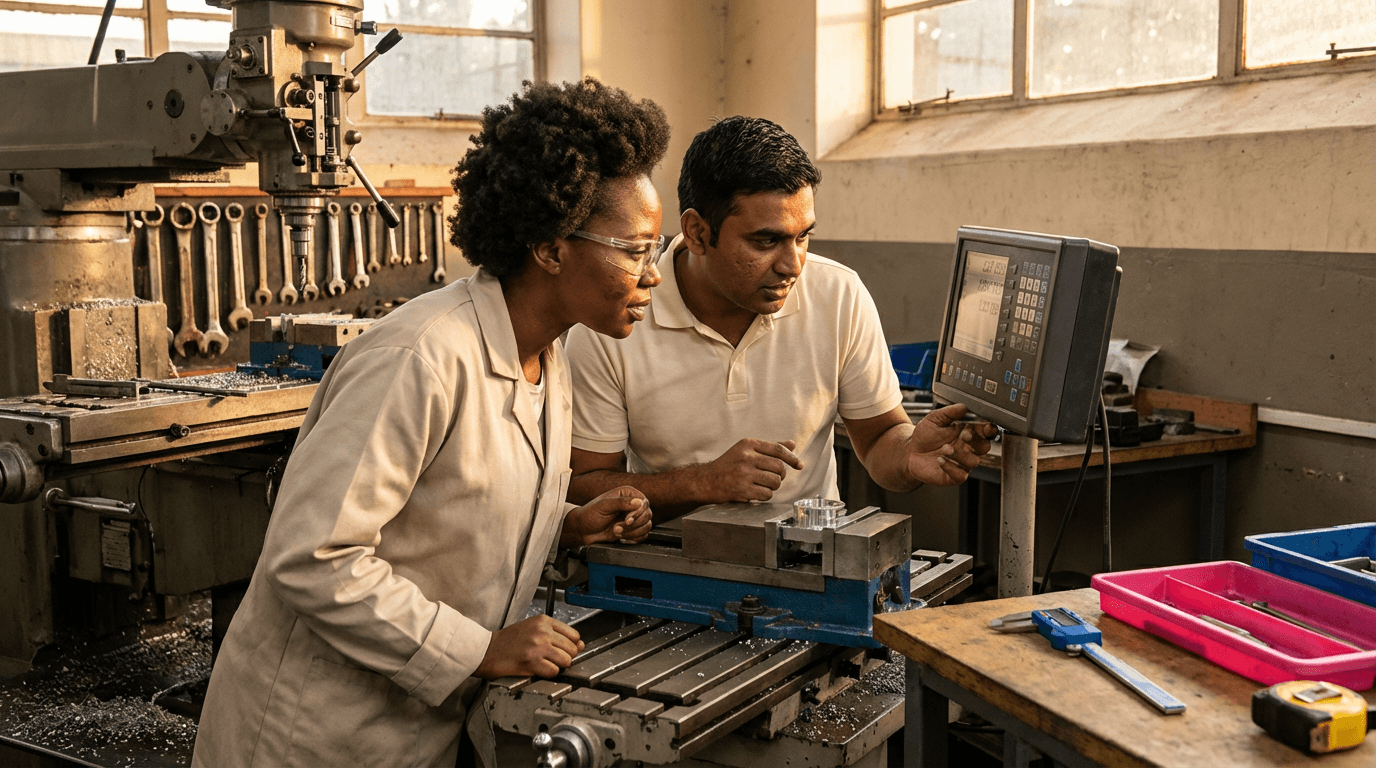

CNC Machining Training

Master CNC machining of high-strength alloy shafts. Learn machine selection, cutting parameters, tool materials, coolant strategy, and quality control to boost productivity, extend tool life, and achieve tight tolerances in demanding metallurgical applications. This course equips you with practical expertise for shop-floor success in processing 32–36 HRC steels.

4 to 360 hours flexible workload

valid certificate in your country

What will I learn?

CNC Machining Training provides practical skills to machine high-strength alloy shafts confidently. Learn machine selection, workholding, cutting parameters, and tool materials for 32–36 HRC steels. Master coolant strategies, toolpath optimisation, surface integrity, and metrology, then apply structured validation and production control to reduce cycle time, enhance quality, and prolong tool life on the shop floor.

Elevify advantages

Develop skills

- CNC shaft machining: set up turning, milling, drilling for hardened alloy shafts.

- Cutting data mastery: pick speeds, feeds, and depths for fast, stable CNC runs.

- Tooling for hardened steels: select inserts, grades, and coatings for long tool life.

- Surface and tolerance control: hit Ra, runout, and geometry specs on gearbox shafts.

- Process optimisation: reduce cycle time, track OEE, and sustain CNC quality.

Suggested summary

Before starting, you can change the chapters and the workload. Choose which chapter to start with. Add or remove chapters. Increase or decrease the course workload.What our students say

FAQs

Who is Elevify? How does it work?

Do the courses have certificates?

Are the courses free?

What is the course duration?

What are the courses like?

How do the courses work?

What is the duration of the courses?

What is the cost or price of the courses?

What is an EAD or online course and how does it work?

PDF Course