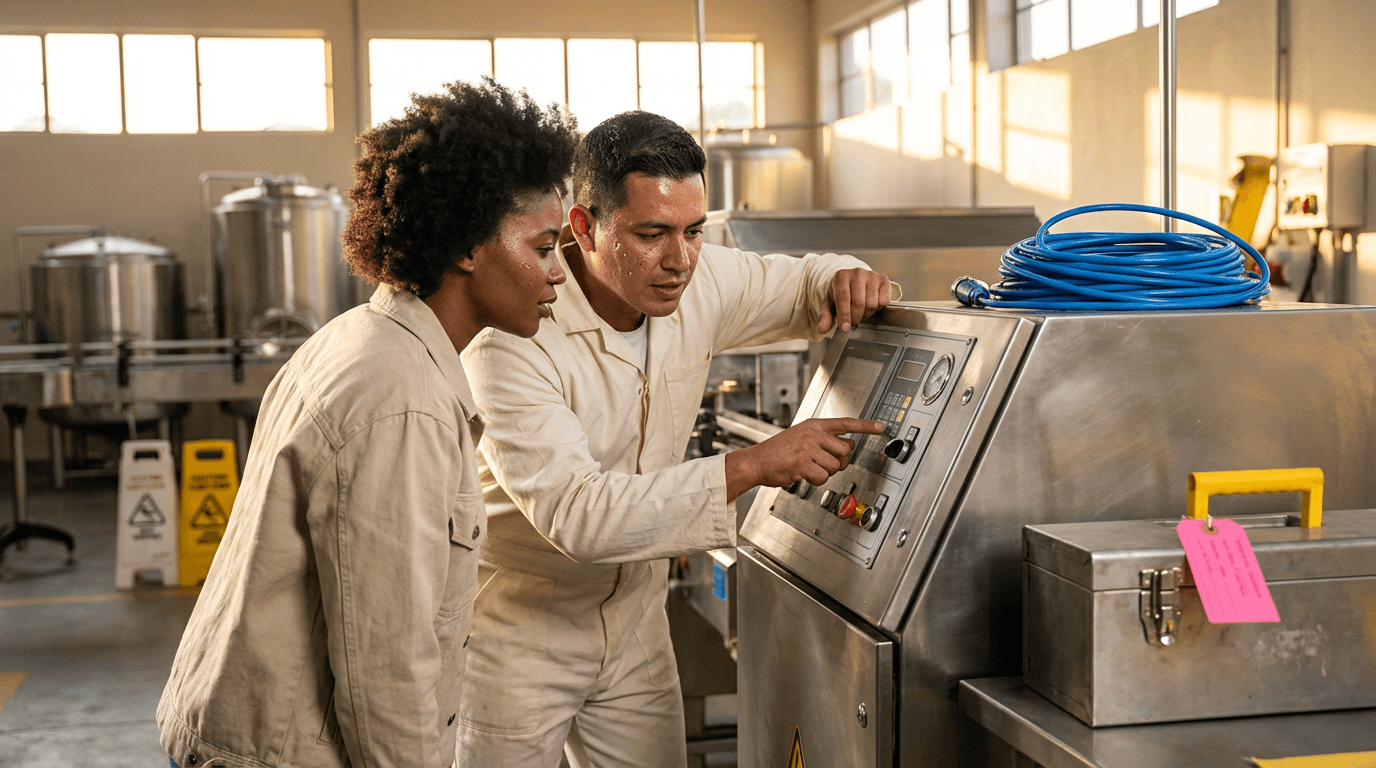

Maintenance of Food Processing Machinery Training

Gain expertise in maintaining food processing machinery while ensuring food safety. The course covers practical strategies, Lockout/Tagout procedures, CIP/COP cleaning methods, contamination control, KPIs, and essential regulatory principles to minimise downtime and maintain hygienic, reliable operation of ready-to-eat production lines.

4 to 360 hours flexible workload

valid certificate in your country

What will I learn?

This training provides practical, step-by-step techniques for maintaining washers, conveyors, cookers, cooling tunnels, and tray sealers safely and hygienically. Participants will learn preventive and predictive maintenance, Lockout/Tagout procedures incorporating hygiene controls, CIP versus COP methods, contamination prevention strategies, Listeria-specific swabbing protocols, key performance indicators, root cause analysis, and procedures compliant with HACCP and FSMA standards.

Elevify advantages

Develop skills

- Hygienic maintenance planning: schedule tasks from washers to sealers achieving zero downtime.

- Food-grade LOTO: isolate equipment, safeguard food-contact areas, and avoid contamination.

- CIP/COP expertise: select, execute, and validate efficient, compliant cleaning processes.

- Environmental monitoring: develop swabbing protocols and respond to Listeria detections.

- Root cause analysis and KPIs: investigate hygiene issues and enhance production line dependability.

Suggested summary

Before starting, you can change the chapters and the workload. Choose which chapter to start with. Add or remove chapters. Increase or decrease the course workload.What our students say

FAQs

Who is Elevify? How does it work?

Do the courses have certificates?

Are the courses free?

What is the course duration?

What are the courses like?

How do the courses work?

What is the duration of the courses?

What is the cost or price of the courses?

What is an EAD or online course and how does it work?

PDF Course