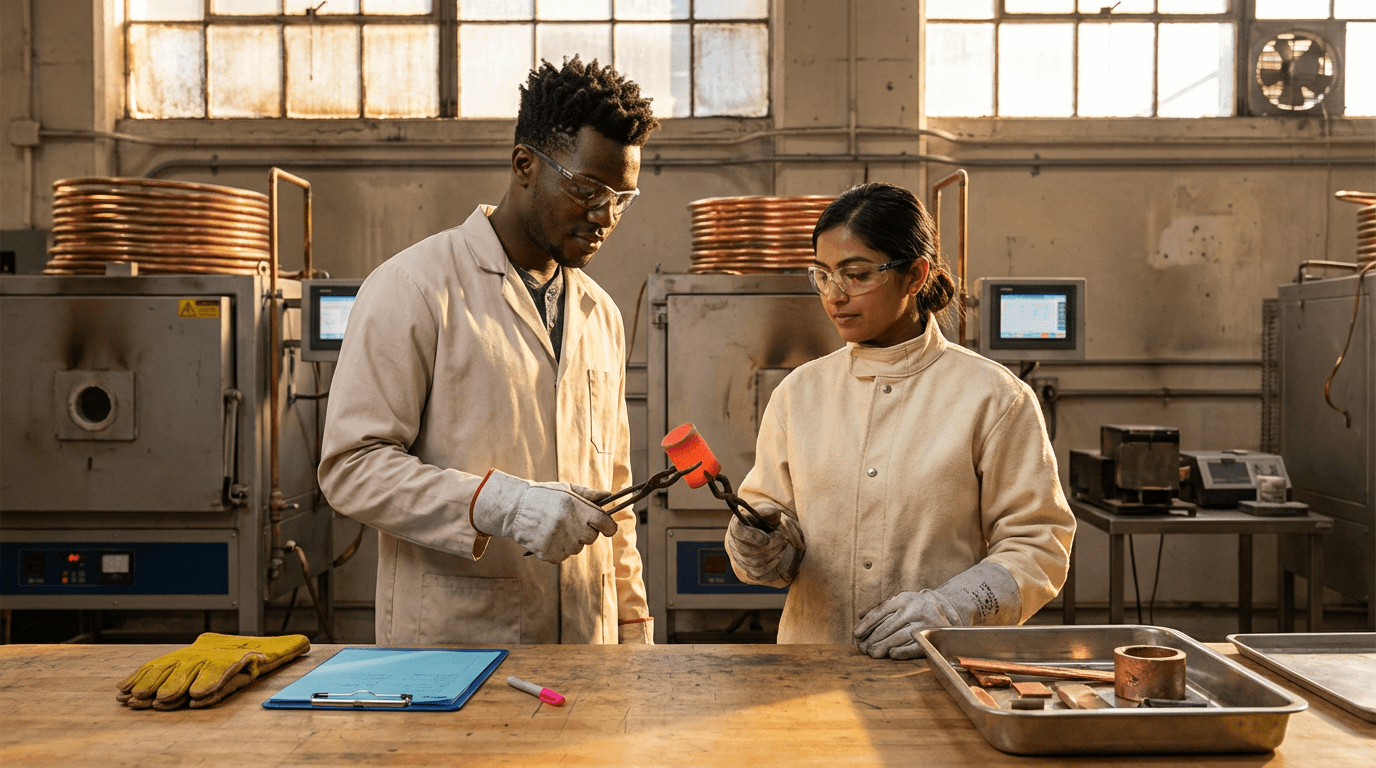

Copper Metallurgy Course

This course delivers practical expertise across the entire copper production chain, from initial ore processing through flotation, smelting, converting, and refining. Participants learn to engineer efficient flowsheets, perform accurate mass balances, control critical impurities, handle byproducts effectively, and ensure high recovery rates with minimal environmental impact and superior cathode quality.

4 to 360 hours flexible workload

valid certificate in your country

What will I learn?

Gain a comprehensive overview of copper production processes, covering ore mineralogy, comminution, flotation, smelting, converting, fire refining, and electrorefining. Master flowsheet design, mass balancing, impurity management like arsenic and sulphur, slag and off-gas handling, pyrometallurgical versus hydrometallurgical methods, and strategies for optimal recovery, reduced emissions, and premium cathode production.

Elevify advantages

Develop skills

- Design integrated copper flowsheets combining crushing, grinding, flotation, and smelting stages.

- Optimise chalcopyrite flotation by adjusting reagents, pH levels, and circuit setups efficiently.

- Manage smelting and converting operations to control matte grade, minimise slag losses, and capture SO2.

- Conduct precise copper mass balances to determine recoveries, blister yields, and impurity distributions.

- Enhance electrorefining processes for achieving 99.99% pure copper with effective impurity rejection.

Suggested summary

Before starting, you can change the chapters and the workload. Choose which chapter to start with. Add or remove chapters. Increase or decrease the course workload.What our students say

FAQs

Who is Elevify? How does it work?

Do the courses have certificates?

Are the courses free?

What is the course workload?

What are the courses like?

How do the courses work?

What is the duration of the courses?

What is the cost or price of the courses?

What is an online course and how does it work?

PDF Course